WHY?

Silver Series

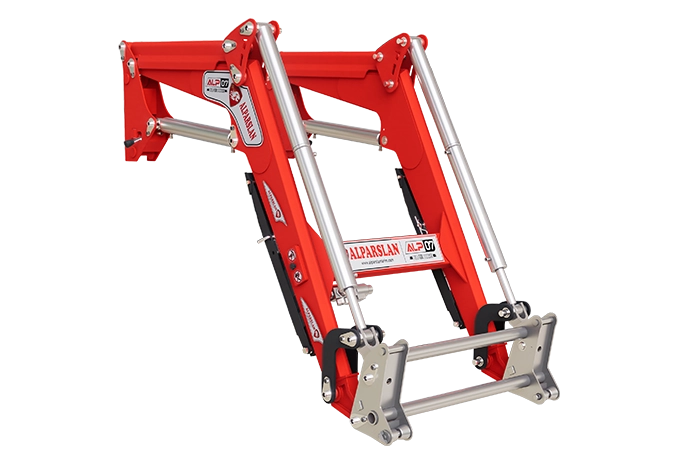

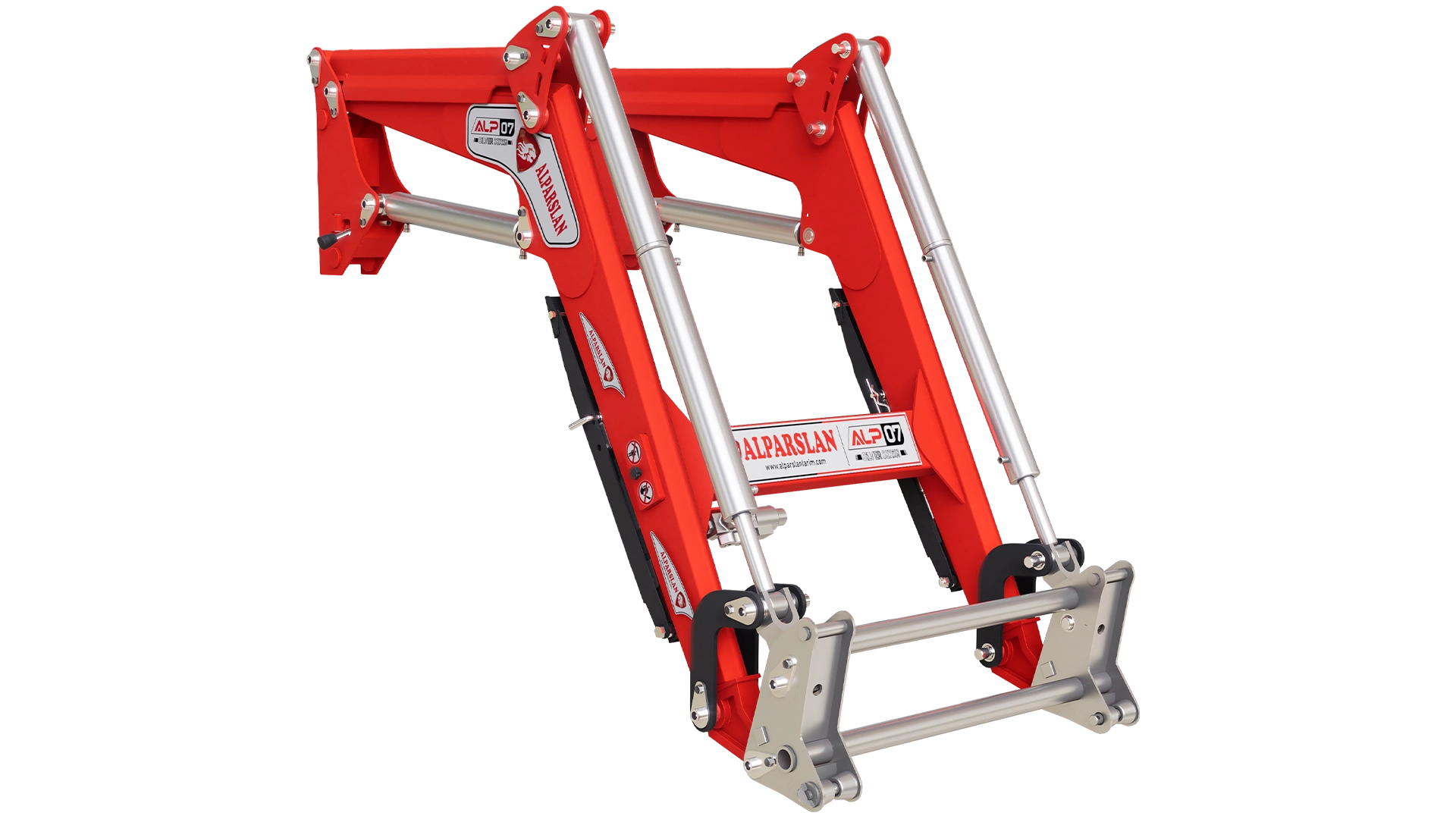

High on the farm: Big tractors are on the rise. Of course, as ALPARSLAN, we also offer the right front loaders for this. Our Silver Series New Generation product reliably passes the toughest tests. Versatility is legendary. He is our pride.

CONVINCING BENEFITS FOR YOU.⦁ Different front loader models perfectly match tractors from 50 to 300 HP.

⦁ Best quality made of fine grain steel for a loader with high torsional rigidity and stability.

⦁ Impressive lifting power and height.

⦁ Z-kinematics and optimum positioning of the cross tube provide the best view of the tool.

⦁ For maintenance work, a standard key is sufficient to access the lines.

⦁ Best equipment, optional feature: return to level, fast unload

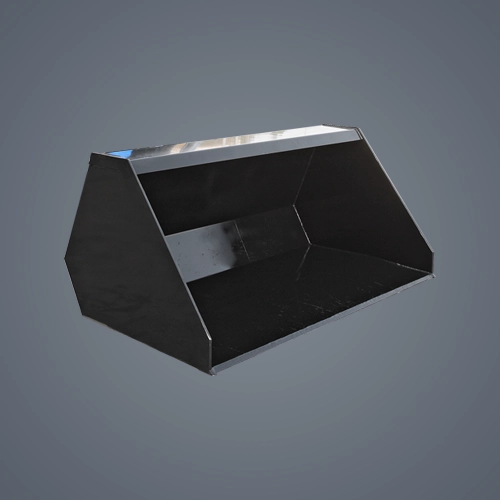

⦁ Re-Bucket Series

⦁ Depending on the loader model, quick-change frames are available for other attachment systems. With ALPARSLAN there is full flexibility.

WE ARE ALWAYS

WITH OUR FARMER!

SINCE 1969

WE ARE WITH THE TURK FARMER!

Turkish engineering world-class high quality, performance and is known for its reliability. For this reason, all Alparslan front loaders have been developed by us in Turkey with exactly these values. They combine the latest technology with innovative solutions - this is our claim to a Turkish quality product.

Experience the full power of the Silver Series Next Generation. Inspiring best values in all areas provide the highest quality in terms of lifting power and lift height, stability or loading speed. On top of that, all Silver Next Generation's individually selectable accessories perfectly suit your wishes as a farmer or contractor. Real professionals for professionals.

• The Silver Series front loaders are thin made of grained steel.Advantage: maximum stability with maximum torsional stiffness at the same time.

• Swing arm is bent from one piece of steel. Control rods are built into the mast. All hydraulic lines are well protected but freely accessible under the swing arm.

• The kinematics of the entire swing arm body have been adapted to modern tractors. This results in an optimal positioning of the swing arm to relieve the front axle and the best possible free space for steering angle and axle rotation.

• We use non-corrosive steel hydraulic pipes in this area to prevent regular replacement of hose lines in the pole area, which is required according to DIN 20066.

Attachment Balancing System

The attachment balancing system is hydraulically designed with 6 lifts on the Uranium and Platinum Series Front Loaders. Its most distinctive feature is that it suspends the load on the front loaders and prevents the mechanical structure of the front loader from being deformed.

Strong Joint Points

The bearings used at all joint points are imported from the world-renowned Italian company CSB and show long-term durability thanks to its bronze-coated surface that does not corrode under heavy loads.

WE JUST HAVE MORE

Bolt diameter of 40 mm from the largest to the smallest loader

Bolt diameter of 45 mm at the top pivot point of the Z kinematics.

Bolt diameter of 50 mm on the rear swingarm shaft.

Anti-Shock Tubes

The Monoblock Control Center, Anti-Shock Tubes, which determine the operation and performance characteristics of the front loader, are imported as Italian WALVOIL brand and the movable attachment hydraulic valve is imported as Italian ARON brand.

Strong Hydraulic Connections

All hydraulic connections on the front loader are easily disassembled and sealed by using flat forehead quick couplings, which are hydraulic connection elements imported from the Italian FASTER company.

SPARE

PARTS

LOWER TRACTOR LOAD AND

HIGH INSTALLATION PRECISION

⦁ Attachments are perfectly suitable for attachment to all common tractors. For this purpose, each tractor model is individually adapted by Alparslan designers.

⦁ Reduced front axle load thanks to optimum positioning of attachments close to the driver's cab. This shifts the center of gravity of the entire front loader to the center of gravity of the tractor.

⦁ The opening of the windshield is usually only possible with an Alparslan attachment.

⦁ Thanks to the individual adaptation to the tractor, the attachments fit perfectly.

⦁ The mechanical parallel link is in the rocker arms, which is the basis of Z kinematics.

⦁ This gives the driver a clear view. There are no interfering parts on the swingarm. Another plus: The front loader can also be mounted closer to the driver's cab - the result: reducing the tractor load thanks to optimally placed attachments.

⦁ No loss of lifting power. Front loaders with Z-kinematics have even higher lifting and tearing forces.

NEW GENERATION

INPUT SYSTEM

NEW GENERATION

INPUT SYSTEM

Alt Thanks to the special connection angle design of the chassis, the ideal distribution of the load on the main body of the tractor is ensured and no parts are removed, thus preventing the steering angles from deteriorating.The attachment balancing system is designed as lift/hydraulic in the Silver Series front loader.

JOYSTICKSingle The joystick is completely ergonomic and, thanks to its small size, allows the operator to easily and fully control all the functions of the front loader.

MOVING ATTACHMENT HYDRAULIC VALVEAttachment Electro-hydraulic installation is ready to use to provide additional hydraulic movement requirement.

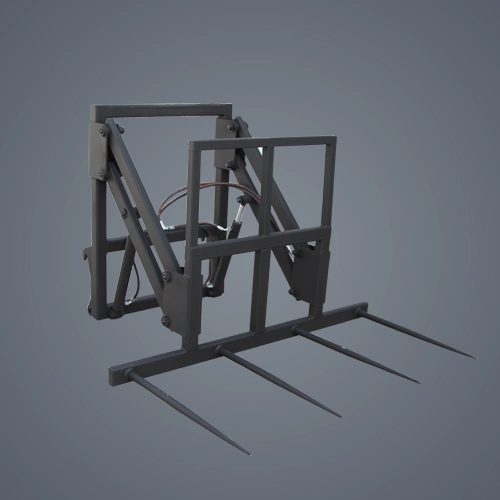

QUICK ATTACHMENT REMOVAL - ATTACHMENT ADAPTERIt is designed to allow quick and easy replacement when it needs to be changed according to the job.

ANTI-SHOCK SYSTEMTwo anti-shock accumulator provides security against jolts and bounces during loading and transportation phases. This system offers comfort and safety to the operator, prevents the load from being unbalanced and overloaded on the tractor, and ensures that the hydraulic system works comfortably and healthily. Shocks and pressures in all parts have been reduced thanks to this system, providing an advantage in terms of speed and load increase.The most distinctive feature is that it suspends the load on the front loader and prevents the mechanical structure of the front loader from being deformed.

BUSH AND PINSAll The cylindrical bushings used at the joint points are selected from bronze materials that do not wear out even under extreme loads. All the pins used in the joint points are manufactured from steel material, galvanized and resistant to corrosion with its non-rusting feature.

NEW GENERATION

INPUT SYSTEM

NEW GENERATION

INPUT SYSTEM

For over thirty years, Alparslan front You could easily connect the loaders to your tractor. And with the function of entering. The Alparslan trolley entry system has been continuously developed for you and its function has been optimized. The good news: Despite all the improvements, one thing has remained unchanged for 30 years: the running-in principle.

Because we believe it is for your benefit. Because your new bootloader will also fit perfectly in our tried and tested console. This system is now part of the core hardware of a bootloader.

Reliable and used over 1/4 million times. By the way, an Alparslan invention. Original from Alparslan. faithful to generations.

READY TO USE IN LESS THAN TWO MINUTES:

THE MOST SUITABLE

SOLUTION

TECHNICAL

INFORMATIONS

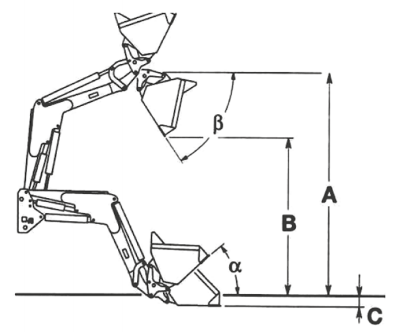

| EXPLANATION | DETAIL |

|---|---|

| Maximum Lift Height(A) | 2200 mm |

| Maximum Lifting Height (Attachment with Ground) | 2100 mm |

| Discharge Height(B) | 1800 mm |

| Maximum Height Carry Angle(A) | 45° |

| Discharge Angle at Maximum Height(B) | 55° |

| Minimum Height Gathering Angle | 45° |

| Breakout Capacity of Attachment from Ground | 750 kg |

| Maximum Height Carrying Capacity | 775 kg |

| Attachment Balancing System | Mechanical |

| Anti-Shock System | Optional |

| Joystick Control System | Standard |

| Movable Attachment Hydraulic Valve | Optional |

| Quick Attach-Attach Adapter | Standard |

| Front Loader Weight | 250 kg |

| Required Tractor Horsepower (HP) Range | 25-40 HP |

+90 444 39 42

+90 444 39 42 alparslan@alparslantarim.com.tr

alparslan@alparslantarim.com.tr +90 444 39 42

+90 444 39 42